Safe, smart and sustainable Food & Beverage

ABB’s commitment to sustainable food future

As we enter a new decade, the challenges and opportunities facing Food and Beverage are extraordinary. F&B manufacturers are under heavy pressure to continually adapt to changing consumer tastes and demands. Every stage of the food value chain, plays a role in shaping safety, quality and the ability to feed the world sustainably. A transformative shift has begun and estimated 86% of leading F&B companies have set specific targets and ambitious goals for change. Beyond energy and emissions, packaging and sustainable logistics are an immediate priority.

As we turn our thoughts to the future, pioneering technology and superior service commitments will remain the key enabler for this transformative shift.

Join us for one or all of the webinars in this Safe, Smart and Sustainable Food & Beverage Expert series to dive into the basics of digitalisation and specific technology examples that can drive energy efficiency, safety and sustainability. Learn how evolving logistic concepts can help you meet your sustainability goals, rethink your strategy to make operations and supply chain more sustainable and agile.

Digital Expert Day: Uncover hidden potential of your plant

Digital solutions for optimal production performance

While the world is asking us to change and to adapt our strategies and operations facing unprecedented situations, we can support you effectively in implementing innovative solutions that will help your business to become more competitive. Maximizing availability and reliability of electrical assets while minimizing risks, increasing personnel safety, reducing operational costs and improving energy efficiency are the key drivers of our solutions and we’ll show you how easy and effective is the implementation into your plant.

Digital solutions for optimal production performance

Fitness wristbands for machinery actually exist. We will disclose to you digital solutions that are scalable and adaptable resulting in improved sustainability and lower total cost of ownership for motors and even powertrains.

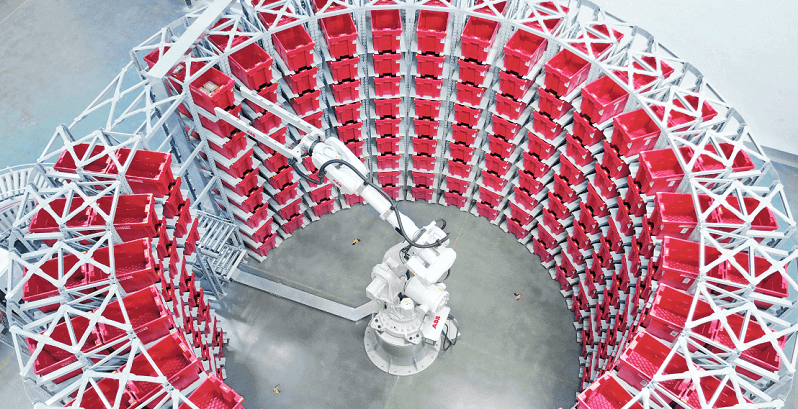

Scalable and flexible robotic automation solutions for F&B

Advanced in robotic technology, such as machine vision and AI, are enabling a higher level of flexibility and scalability in the automated solutions for F&B packaging and distribution. We are helping our customer in removing bottlenecks and reducing the overall lead-times, which is essential in perishable supply chains.

Gaining competitive advantages through manufacturing operations management software

Food and beverage makers today operate in a highly competitive market. In addition to fierce cost pressure, high demands are on uncompromised safety, hygiene, sustainability and traceability.

Learn how ABB’s Manufacturing Execution System enables higher plant efficiency and productivity as well as greater flexibility throughout the production processes by providing seamless orchestration and synchronization of all the entities involved in the F&B process.

Service Expert Day: Rethink your service strategy

Meet your sustainability goals by optimizing efficiency of electrical assets and minimizing impact of unforeseen events

As companies change their business models to match their strong sustainability goals, rethinking their service strategies could help get them there. This webinar will explore service best practices that reduce waste during unnecessary maintenance, optimize efficiency through upgrades and much more.

How to improve OEE and energy efficiency by modernizing your aging production assets

Improved sustainability is a key priority to many F&B companies. The combination of taking a global responsibility and lowering costs is delicate and a must.

This session will talk about how to lower life cycle costs through assessments that identify how to prioritize efforts in upgrading and modernizing machinery in your production.

Uncover hidden potential of your operations with robotics digital services

Connect your robot today to unlock advanced services for up to 25% fewer incidents, 60% faster response time and measurable production increase.

Monitor the health and performance of a single robots or entire fleet, run robot systems at optimal performance and use virtual technical assistance to reduce production downtime.